Fired Heater Design & Manufacturing

In addition to our first-class fabrication, Exotherm is known for offering a safe and robust control system. Exotherm can design safe and dependable fired heaters for nearly any application, including thermal fluids, vegetable oils, some crude oil applications, and regeneration gas heaters. We work with customers who are looking for high-quality process heaters. We design and manufacture process heaters for a wide range of industries including, petrochemical, oil & gas, power & utilities, food processing and manufacturing.

UNIFLUX Advantages

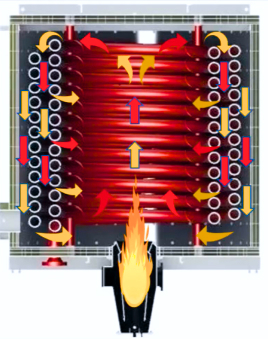

Don’t gamble with your process heater. When it comes to performance, reliability, and safety, the UNIFLUX heater has no equal.

The UNIFLUX heater has significant process heater advantages over competitive fired heaters. The convective heat transfer method of the UNIFLUX heater allows for unparalleled heat transfer uniformity to your process fluid.

ADVANTAGES INCLUDE:

- Extreme Durability

- Compact

- Fast Response

- High Heat Release Rates

- Minimum Flame Extension

- Stoichiometric Combustion

- Safe Operation